C-Stainless ice builders are a versatile cooling option for your processing plant. They work well for cooling milk after vat pasteurization, cooling plate packs, and cooling ice cream tanks.

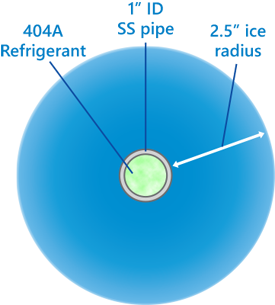

An ice builder is a large water tank with cooling pipes running through it. A compressor pumps cold refrigerant through the pipes, causing ice to accumulate on the pipes. This ice chills the water in the tank.

The cold water is then available for cooling in your plant. As the cold water is used, it becomes warm. When this water returns to the ice builder, it depletes the supply of ice. Because of this, an ice builder needs downtime to rebuild its ice bank. The downtime will vary depending on your processing environment.

Ice builders and chillers are two different cooling solutions for a processing plant. To decide which to buy, you’ll have to consider your specific needs. Chillers work well if you need a steady amount of cooling over a long period of time. Ice builders work best if you need large amounts of cooling at specific times during the day. Here are some more factors to consider: